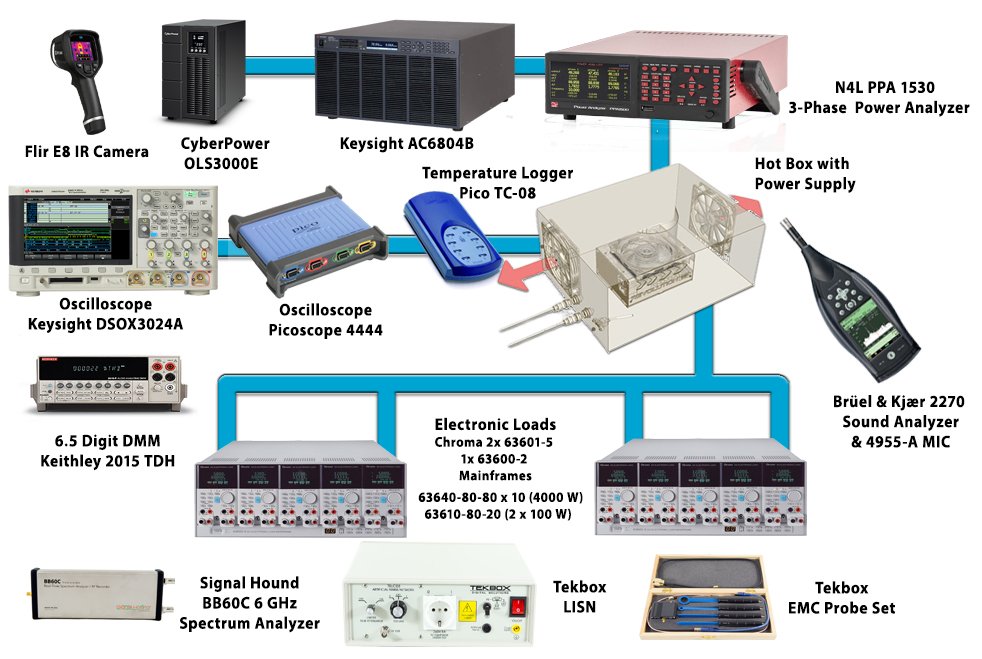

, die bis zu 3 kW Leistung und eine Chroma 61604 mit max. 2 kW Leistung liefern kann. Beide Wechselstromquellen sind über zwei leistungsstarke Trenntransformatoren (3 kW) mit dem Netz verbunden und für die beiden programmierbaren Wechselspannungsquellen vom Typ Chroma 6530 und Keysight AC6804B verwenden wir zudem je eine unterbrechungsfreie Stromversorgung vom Typ CyberPower

Unsere elektronische Lastsammlung umfaßt auch zehn Array-Einheiten (sieben Array 3711A und drei Array 3710A) und zwei Fast Auto FA-828ATE.

Wir verwenden die folgenden Oszilloskope: ein Keysight Technologies DSOX3024A, ein Rigol DS2072A, ein Picoscope 4444 und ein Picoscope 3424. Uns stehen noch vier weitere Oszilloskope zur Verfügung: Rigol DS1074Z, Rigol VS5042, Stingray DS1M12 und ein zweites Picoscope 3424.

Der Rest unserer Ausrüstung besteht aus einem Picotech TC-08 Thermoelement-Datenlogger, zwei Fluke Multimeter (Modelle 289 und 175), ein Keysight Technologies U1273AX Multimeter, ein Keithley 2015 THD 6,5-Digit Bank DMM und ein Labor Grad N4L PPA1530 3-Phasen-Strom Analysegerät. Für Backup-Zwecke haben wir einen Yokogawa WT210 Power Analyzer und einen GW Instek GPM-8212.

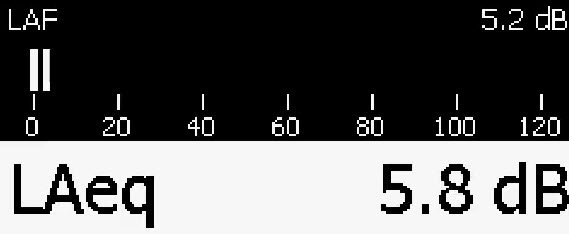

Die Geräuschmessungen werden mit einem Analysator der Klasse 1

Bruel & Kjaer 2250-L G4 durchgeführt, der mit einem

Mikrofon Typ 4955-A ausgestattet ist, das einen 5-110 dBA-gewichteten Dynamikbereich aufweist. Der Schallanalysator ist in eine maßgeschneiderte echofreie Kammer eingebaut, die weniger als 6 dB (A) Umgebungsgeräusche ermöglicht. Ein Bruel & Kjaer

Typ 4231 wird vor jeder Geräuschmessung verwendet, um den Schallanalysator zu kalibrieren.

Wir sind in der Lage Auswertungen die elektromagnetische Verträglichkeit (EMV) betreffend durchzuführen, da unser Labor mit einem Rigol DSA815-TG Spectrum Analyzer (9 kHz - 1.5GHz) ausgestattet ist, mit der EMI-Option. Wir verwenden auch eine Tekbox TBLC08 LISN, um das Stromnetz von dem Gerät in diesem Test (DUT) zu isolieren. Unser zweiter Spectrum Analyzer ist ein Signal Hound BB60C. Um die EMI-Quelle zu identifizieren, sollten wir eine Reihe von Tekbox-EMV-Sonden (TBPS01) und einen TBWA2- Breitbandverstärker zur Verfügung haben.

Wir führen alle Tests bei über 30 °C Umgebung durch, um die Umgebung in einem typischen System genauer zu simulieren. Dazu verwenden wir eine maßgeschneiderte Kammer, ausgestattet mit Heizelementen, die über Software gesteuert werden und automatisch die gewünschte Temperatur innerhalb der Kammer einstellen können.

Was uns einen Vorteil gegenüber allen übrigen Labors gibt ist die maßgeschneiderte Software, die für alle unsere Anlagen, von den elektronischen Lasten und der Power Analyzer auf den Temperaturlogger und die elektromagnetische Relais zu steuern, die die Wärme im Inneren der Wärmekammer steuern. Der Entwicklungsprozess dieser Software hört nie auf, da wir sie ständig mit neuen Features bereichern.